SYPRO® DUAL 200

The system runs on intermittent as well as continuous motion blister machines. With this highly efficient feeder system HMH offers you one solution for blister machines with plate sealing or rotary sealing, to be switched simply via software control. The feeder system is a self-contained unit that communicates with the blister machine only via signals.

The Sypro® Dual 200 feeder system can hold feeder cassettes for draw offs up to 500mm. The unit is run by electricity and all motions are servo-controlled. This allows for very fine adjustments of the stopper pins to allow for different product shapes. All motions are controlled using servo motors, therefore no risk of air contamination.

All settings and adjustments are managed via the touch screen control panel. The design is very user friendly and product settings can be saved / recalled as recipes, thus reducing changeover times.

- The feeder is exclusively driven electrically and does not use pneumatics. Thus, no external air in the environment of open products.

- GMP fair design.

- Visualization is FDA CFR Part 11 compliant.

- Networking capability.

- Remote Access capability.

- All axes with absolute position detection.

- Multilingual operation, languages switchable.

- Detailed error description with possible root cause analysis to assist in the elimination of any errors.

- An unlimited number of format recipes can be stored.

- Product recipes can be exported and imported.

- Creation of PDF-files to output product recipes and audit trail information.

- All axes and functions can be changed during operation.

- Four user levels with different permission settings for as many users as desired

- Login via username and password with auto-logoff possibility.

- If there is no enable signal on the blister machine, it is possible to use the feeder’s own shift register.

Intermittent blister machines (plate sealing):

- Sweep movement of the X-Y axis after or during the placement of the products in the blister pocket. The sweep movement can be adjusted in length and angle.

- Web shrinking compensation optionally available.

- It is selectively possible to fill the products during each sealing cycle or to fill a double cycle every second sealing cycle. The maximum numbers of cycles of the feeder are 60 feeding cycles, thus up to 120 sealing cycles per minute.

Continuous motion blister machines (rotary sealing):

- 100% synchronization with the web-speed. The speed of the web can be varied between 0-20m / min. during operation.

- Pocket edge-triggering or blister machine signal-triggering optionally configurable.

- The length of the feeding cycle can be adjusted independently of the deep drawing cycle to the required feeding rate.

|

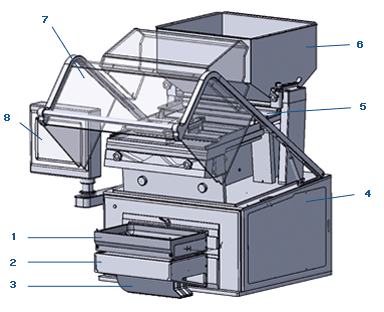

1. Tray (Format) 2. Separation unit (Format) 3. Filling shoe (Format) 4. Drive assembly (main unit) 5. Linear conveyer 6. Hopper 7. Safety guard 8. Human machine interface (Touch Screen)

|

|

Dimensions of mechanical parts |

||

|

Depth of the drive housing: (space requirement behind guide rail) |

|

650 mm

|

|

Width of the drive housing: (with standard guard) |

|

700 mm

|

|

Height of drive housing |

|

410 mm |

|

Travel to web |

|

35 mm |

|

Travel along web (max) |

|

170 mm |

|

Weight drive unit (without conveyer or formats) |

|

ca. 130 kg

|

|

Performance data |

||

|

Max. feeding index length |

|

500 mm |

|

Max. web width |

|

350 mm |

|

Feeding capacity intermittent |

|

60 cycles/Min |

|

Feeding capacity continuous |

|

20 m/Min |

|

Electrical Requirements |

||

|

Voltage |

|

3x 400 V |

|

Frequency |

|

50 / 60 Hz |

|

Power consumption |

|

6A |